Typical spindle structure and bearing selection for several heavy-duty CNC vertical lathes (I)

Release Time:2025-02-28

Source:

The current market requirements for the equipment manufacturing industry are: higher flexibility; higher productivity; higher precision and surface quality; shorter manufacturing cycle to meet the market.In recent years, with the booming development of the domestic equipment manufacturing industry, as the mother machine of the equipment manufacturing industry is more prominent position, in order to adapt to the needs of a variety of industrial enterprises, machine tool manufacturers have introduced high-precision machine tools.

With the acceleration of China's industrial heavy-duty process, more and more machine tool companies recognize the value of heavy-duty machine tool field and business opportunities, and is ready to gradually join the major type of machine tool market competition, and in recent years, with the commercialization of high-tech functional components of CNC machine tool products, to participate in the development of the market for heavy-duty machine tools are also more and more enterprises.

Now the development trend of heavy machine tools are mainly in the following areas: The demand for machine tool carrying capacity is growing; Users require more and more large rotary diameter of the machine tool; Large rotary diameter, high precision requirements of large weight machine tools. Spindle as the core part of the machine tool, the rotary accuracy of the spindle will be a direct response to the roundness of the machined part, cylindricity, runout and other precision, and the machine tool adopts the spindle structure will affect the machine tool rotary diameter and table carrying capacity. The spindle structure adopted by the machine tool will affect the rotary diameter of the machine tool and table loading capacity.

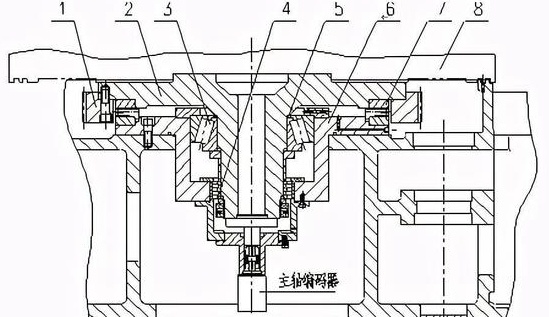

Structure I

Structure I consists of transmission ring 1, spindle 2, tapered roller bearings 3, double row cylindrical roller bearings (cylindrical hole) 4, adjusting pads 5, bearing bush 6, thrust cylindrical roller bearings 7, worktable 8 and other components. The power is transmitted from the gear ring to the spindle, the spindle drives the table to realize the rotation of the workpiece, and the spindle encoder is installed at the bottom of the spindle to feedback the spindle speed.

The bearing layout in this structure consists of double row cylindrical roller bearings + tapered roller bearings + thrust cylindrical roller bearings, double row cylindrical roller bearings + tapered roller bearings for the spindle centering bearings, responsible for carrying the axial force and radial force of the spindle, of which tapered roller bearings are the main support, the inner and outer rings with the spindle and the bearing bush with the clearance will have a direct impact on the radial runout of the spindle and the spindle rigidity; Thrust cylindrical roller bearings Thrust cylindrical roller bearings are mainly used to carry the weight of the workpiece and the cutting force loaded onto the table during the cutting process, the tight and loose rings of the bearings are matched with the upper face of the bearing sleeve and the lower face of the spindle, which will directly affect the axial runout of the spindle.

For further information, please contact:

Sundy Liu ; sundyliu@lzjmbearing.com

Key words:

Online message