Typical spindle structure and bearing selection for several heavy-duty CNC vertical lathes (II)

Release Time:2025-03-06

Source:

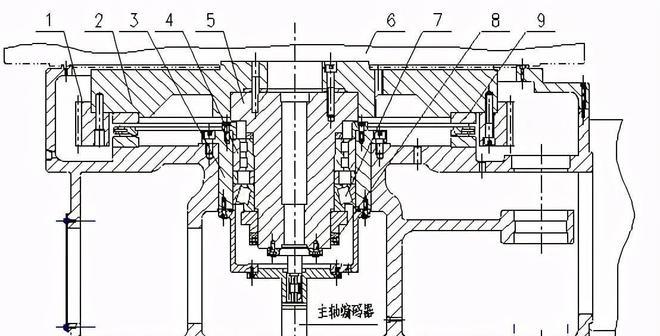

Structure II

Structure II consists of gear ring 1, transition disk 2, bearing bush 3, double row cylindrical roller bearing (tapered hole) 4, spindle 5, table 6, tapered roller bearing 7, lock nut 8, thrust cylindrical roller bearing 9 and other components. The power is transmitted to the spindle by the gear ring, the spindle drives the table to realize the rotation of the workpiece, and a spindle encoder is installed at the bottom of the spindle to feedback the spindle speed.

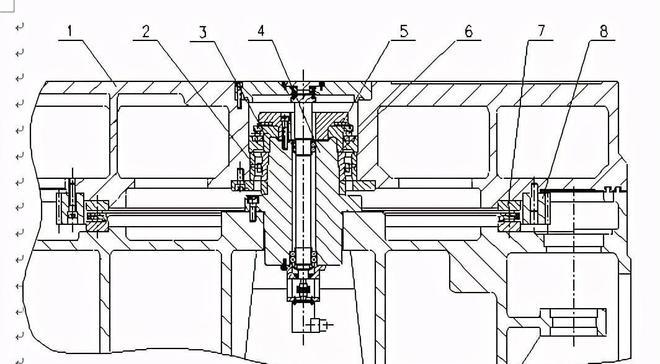

Structure III

Structure III consists of table 1, double row cylindrical roller bearings (tapered bore) 2, thrust ball bearings 3, spindle 4, butterfly spring 5, flange 6, thrust cylindrical roller bearings 7, transmission ring 8 and other components. The power is transmitted from the gear ring to the spindle, which drives the table to realize the rotation of the workpiece, and a spindle encoder is installed at the bottom of the spindle to feedback the spindle speed.

This structure spindle consists of double row cylindrical roller bearings (tapered bore) + thrust ball bearings + thrust cylindrical roller bearings, the first two bearings are centering bearings, responsible for carrying the spindle axial force and radial force, which double row cylindrical roller bearings (tapered bore) is the main support; thrust cylindrical roller bearings are mainly loaded with the weight of the workpiece and in the cutting process of the cutting force loaded to the worktable.

This structure spindle preload force through the grinding flange 5 of the lower end of the realization of the upper end of the spindle butterfly spring can effectively reduce the spindle vibration on the spindle end of the impact of runout; and spindle centering bearings and bearings do not go through the transition plate or spindle sleeve directly with the table, greatly reducing the difficulty of its machining and assembly, and at the same time to improve the rotary accuracy, so that the spindle's overall rigidity is greater.

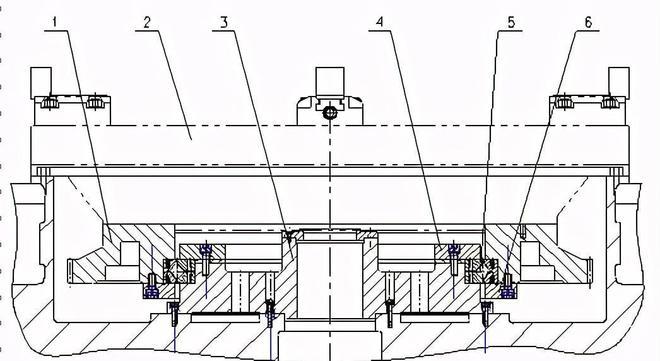

Structure IV

Structure IV consists of table 1, bearing support 2, angular contact ball bearing 3, adjustment pad 4, spindle 5, thrust ball bearing 6, transmission ring 7 and other components. The power is transmitted to the spindle by the gear ring, and the spindle drives the table to realize the rotation of the workpiece, and there is an angle encoder installed in the middle of the spindle to feedback the spindle speed.

Structure IV is a subversion of any previous heavy vertical spindle structure, it is centered by the angular contact ball bearing, thrust ball bearing, because the rolling body of the bearing is a ball, so the rotary accuracy and speed of this structure is much higher than the above three spindle structure.

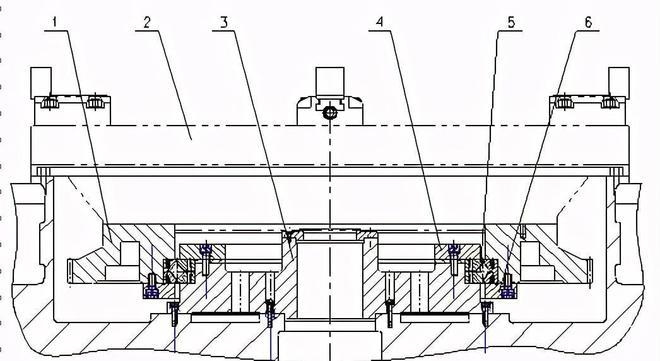

Structure V

Structure V consists of transmission ring 1, table 2, spindle 3, upper pressure plate 4, cone cross roller 5, lower pressure plate 6 and other components. The power is transmitted to the spindle by the gear ring, and the spindle drives the table to realize the rotation of the workpiece, and there is an angle encoder installed in the middle of the spindle to feedback the spindle speed.

Structure V is currently more popular in Europe and the United States and Japan and South Korea, a new type of heavy vertical lathe spindle structure, which uses a tapered crossed roller bearings instead of the traditional 2-3 bearings of the structure, the tapered crossed roller bearings and bearing the established center of the bearing workload, the upper inner ring, the lower inner ring, the outer ring and the related spindle, gear ring through the heating or freezing to achieve a larger amount of surplus to ensure that the spindle's rotary accuracy and Load carrying capacity.

For further information, please contact:

Sundy Liu ; sundyliu@lzjmbearing.com

Key words:

Online message