Typical spindle structure and bearing selection for several heavy-duty CNC vertical lathes (III)

Release Time:2025-03-07

Source:

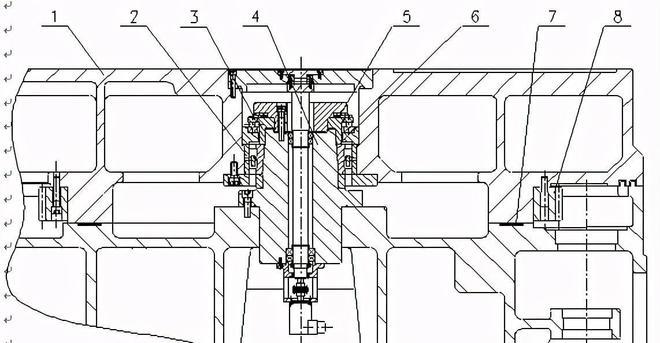

Structure VI consists of table 1, double row cylindrical roller bearings (tapered hole) 2, thrust ball bearings 3, spindle 4, butterfly spring 5, flange 6, hydrostatic oil chamber 7, transmission ring 8 and other components. The power is transmitted to the spindle by the gear ring, and the spindle drives the table to realize the rotation of the workpiece, and there is a spindle encoder installed at the bottom of the spindle to feedback the spindle speed.

Structure VI

This structure spindle consists of double row cylindrical roller bearings (tapered bore) + thrust ball bearings + hydrostatic plane bearings, the first two bearings are centering bearings, responsible for carrying the spindle axial force and radial force, which double row cylindrical roller bearings (tapered bore) is the main support; hydrostatic plane bearings are mainly loaded with the weight of the workpiece and in the process of cutting loaded to the cutting table cutting force.

In general, the structure of structure I and structure II table diameter does not exceed φ2000mm, the maximum weight of the workpiece does not exceed 10000kg, the spindle speed does not exceed 400rpm, structure II is more reasonable than the structure of a while; structure III, the structure is more reasonable in general, generally used in the table diameter does not exceed φ3150mm, the maximum weight of the workpiece does not exceed 20000kg, the spindle speed does not exceed 250rpm; the above three structures are the more traditional structure of heavy vertical lathe, most manufacturers at home and abroad will basically have a more similar structure. More than 250rpm; the above three structures are the more traditional structure of the heavy vertical lathe, most manufacturers at home and abroad will basically have a similar structure.

Structure IV is a new structure, with the large size of the thrust ball bearing technology breakthroughs, more and more applications in the heavy vertical lathe, the table diameter can reach φ4000mm, the maximum weight of the workpiece is not more than 35,000kg, the spindle speed can reach a maximum of 600rpm, due to its speed can reach a higher level, so it is more suitable for high-speed high-finish machining; structure V is a new structure popular in the past two years! Many years ago, this structure has appeared in Europe and the United States of America's heavy vertical car, but due to the tapered roller bearings at that time, although the bearing capacity is larger, but its limit rotational speed has not been mentioned at a higher level, so the application at that time is a certain limitation, in recent years, with the taper cross roller bearings manufacturer's technology has broken through the limit rotational speed bottlenecks, so more and more manufacturers of heavy-duty trucks loved, and the worktable diameter can reach φ45000kg, the spindle speed can reach 600rpm. The table diameter can reach φ4500mm, the maximum workpiece weight is not more than 40000kg, and the spindle speed can reach up to 500rpm.

Structure VI general application table diameter φ4000mm or more, the maximum workpiece weight of 50000kg or more, of course, the structure can also be used in less than the above two conditions, but due to the later maintenance, maintenance and repair is more cumbersome, the general diameter of the table is not too large or the weight of the workpiece is not too large, the user is less likely to choose this structure.

The previous paragraph describes the table speed and maximum workpiece weight and the specific selection of bearing brand, bearing type and bearing lubrication has a great relationship, not blindly according to the previous paragraph simply into the seat; on the bearing lubrication is not only related to the rotational speed of the table, but also has a great relationship with the table's floating, so in the specific design process should be fully considered lubricating oil flow, lubrication of the piping, the thermal symmetry of the spindle and the lubricating oil. Therefore, in the process of specific design, the flow of lubricant, lubrication piping, thermal symmetry of spindle parts and temperature control of lubricant should be fully considered.

Each of the above six structures has its own characteristics and the scope of application is not the same (there may be overlap), mainly based on the diameter of the table, the table's load-bearing capacity, each manufacturer's machining and assembly capacity, the spindle structure components of the material cost of the total cost of materials accounted for the proportion of the equipment, and so on, trade-offs, in particular, should be considered in different cutting conditions (for example, continuous or intermittent cutting, whether the machined parts have a bias load). Especially should consider different cutting conditions (such as continuous or intermittent cutting, whether the machined parts have partial load, etc.), discretionary selection of appropriate spindle structure.

For further information, please contact:

Sundy Liu ; sundyliu@lzjmbearing.com

Key words:

Online message